Robotics warehousing and floor logistics vary drastically and there is no one-size-fits-all solution. Reliable warehousing, cross-docking efficiency, operational self-driving, and loading/unloading vehicles constraints require specific robotics designs and implementations.

ArquTec Solutions helps with the selection process, development, and deployment of a robotics implementation that meets your requirements and realizes your ROI, ensuring a high percentile online system that is productive, streamlines processes, and reduces operational costs.

Warehousing Automation increases output, improves quality, increases production rates, increases quality in assembly, decreases re-work, fills orders faster, and much more!

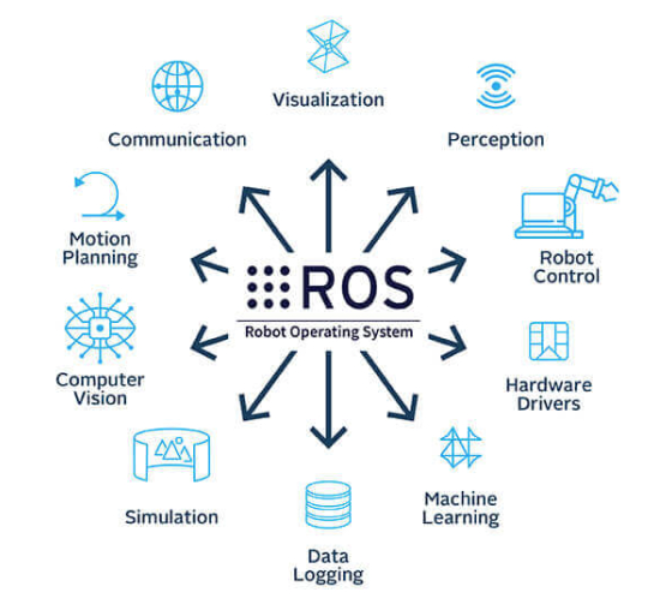

Warehousing and floor logistics, technology integrations, and operational constraints are a challenge in robotics software development, and sensor and hardware selection. ArquTec Solutions identifies the ideal tech stack and hardware and developes customize robotics solutions to your exact requirements.

ArquTec Robotics Solutions provides:

✓ (1) Robotics algorithms development and execution.

✓ (2) Full autonomous development and control.

✓ (3) Machine vision development, including learning and 360 degrees cameras processing.

✓ (4) Motor and motion control development.

✓ (5) Point-to-point navigation development.

✓ (6) Sensors integration development.

✓ (7) Battery management and low power optimization development.

✓ (8) Signal processing development and implementation.

✓ (9) Middleware design, development, and integration.

✓ (10) Robotics collaboration implementation and integration.

✓ (11) Data security and safety controls development and integration.

✓ (12) Robotics self-test and calibration development and implementation.

✓ (13) Warehousing dashboard software development for real-time visibility,

machine performance monitoring, downtime and faults insight, and alerts.

✓ (14) Warehousing simulation development.